THÔNG SỐ KỸ THUẬT

| MODEL |

Unit |

MCV-2100 MCV-2100B |

| TABLE |

| Working Surface |

mm (inch) |

2300x970 (90.55 x 38.19) |

| T-slots (Size x Number) |

mm (inch) |

22 x 5 (0.87 x 5) |

| Max. Table Load |

kgw (lbs) |

3000 (6600) |

| TRAVEL |

|

|

| Longitudinal Travel (X) |

mm (inch) |

2100 (82.68) |

| Cross Travel (Y) |

mm (inch) |

850 (33.4) |

| Headstocl Travel (Z) |

mm (inch) |

760 (29.92) |

| Distance Between Spindle End and Table Top |

mm (inch) |

200-960 (7.87-37.8) |

| Distance Between Spindle Center and Column Surface |

mm (inch) |

850 (33.46) |

| SPINDLE |

|

|

| Spindle Nose |

|

N.T.50 |

N.T.40 |

| Spindle Speeds |

R.P.M. |

6000 |

8000 (10000) |

| Spindle Speed Range |

|

Two Gears Variable |

Infinite Variable |

| FEED |

|

|

|

| Cutting Feed |

mm/min (inch/min) |

10000 (393.7) |

| Rapid Traverse |

m/min (inch/min) |

10/10/8 (393.7/ 393.7/ 314.96) |

| Minimum Input Increment |

mm (inch) |

0.001 (0.0001) |

| ATC (Automatic Tool Changer) |

|

|

|

| Tool Holder |

|

BT50 |

BT40 |

| Tool Storage Capacity |

Tools |

30 |

30 |

| Max. Tool Dia. x Length |

Ø x mm (inch) |

110 x 350 (4.33 x 13.78) |

76 x 300 (3.0 x 11.8) |

| Max. Tool Weight |

kgw (lbs) |

15 (33) |

7 (15.4) |

| Max. Tool Dia. of adjacent pots are empty |

Ø x mm |

200 |

— |

| Tool Selection |

|

Random |

| MOTORS |

|

|

|

| Spindle Drive Continuous Rating |

Kw (HP) |

15 (20) |

11 (15) |

| Motor Rated Output for 30 Minutes |

Kw (HP) |

18.5 (25) |

15 (20) |

| Drive Motors X, Y, Z Axis |

Kw (HP) |

3 (4), 3 (4), 3 (4) |

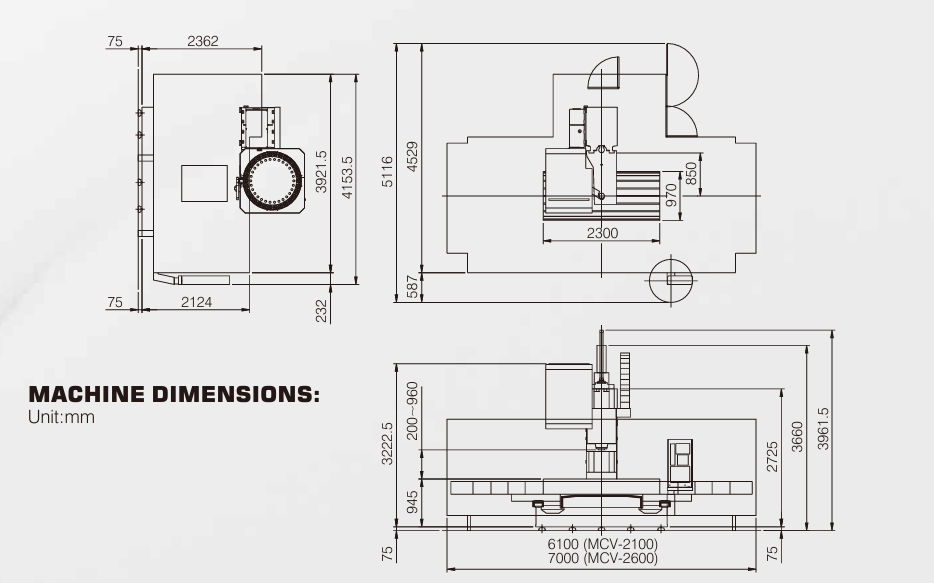

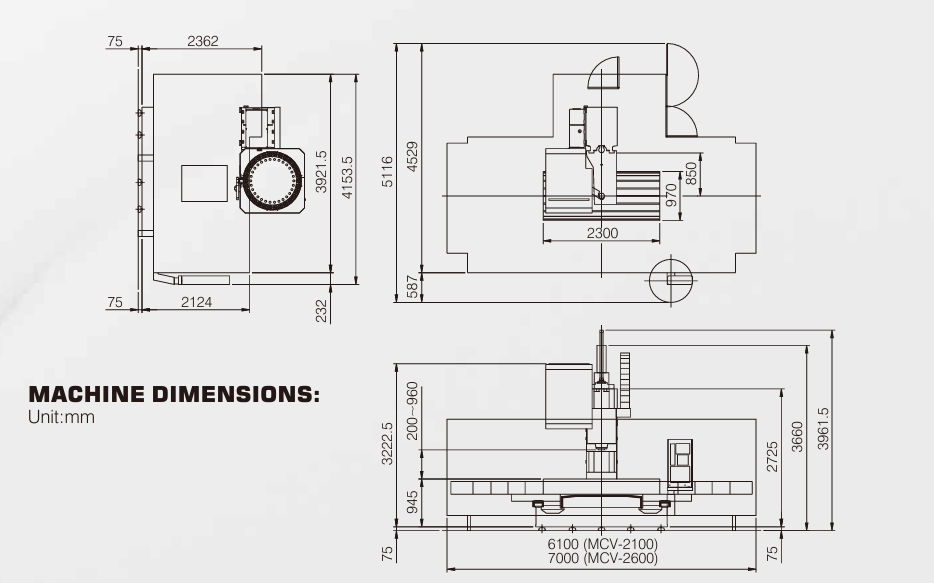

| MACHINE WEIGHT SPACE AND PACKING |

|

|

|

| Floor Space |

mm |

7700 x 4694 |

8600 x 4694 |

| inch |

303.15 x 184.80) |

338.58 x 184.80 |

| Net Weight |

Kgw (lbs) |

18000 (39600) |

19000 (41800) |

LINH KIỆN TIÊU CHUẨN

1. Heat Exchenger

2. Removable Manual Pulse Generator

3. Coolant Around Spindle

4. Spiral Type Chip Conveyor

5. Semi-enclosed Splash Guard

6. RS-232 Interface

7. Automatic Power Off

8. Call Light

9. Automatic Lubrication Equipment

10. Work light

11. Tool Kit

12. Space Fuses

13. Pendant Type Operator Panel

14. Spindle Cooler

15. Rigid Tapping

LINH KIỆN TÙY CHỌN

1. Enclosed Splash Guard

2. Flat Type Chip Conveyor and Chip Wagon

3. Rotary Table With 4

th Axis Control

4. Coolant Through Tool

5. Coolant Through Spindle With Filter

6. Coolant Wash

7. Automatic Tool Length Measuring Device

8. Automatic Centering Device (Renishaw MP-10)

9. Automatic Pallet Changer

10. Cam Mechanism ATC (40 Tools)