- Trang chủ

- Giới thiệu

- Sản phẩm

-

- Thương Hiệu

- Dịch Vụ

- Tin Tức

- Liên Hệ

- TUYỂN DỤNG

- Đăng Nhập

Đăng ký nhận bản tin của chúng tôi và là người đầu tiên biết về phiếu giảm giá và chương trình khuyến mãi đặc biệt

English

Japanese

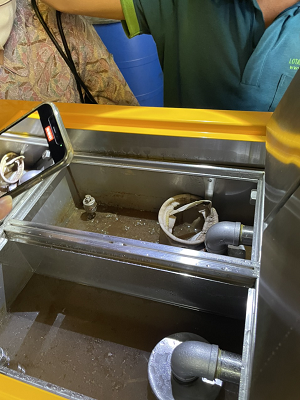

Máy làm sạch ống dẫn khuôn áp dụng công nghệ bằng sáng chế quốc gia, sử dụng nguyên lý Cavitation- tạo bong bóng trong nước, cần kết hợp không khí có áp suất cao và nước có áp suất cao với nhau và giải phóng hỗn hợp theo dạng các sóng xung kích. Áp suất không khí và tần số xung có thể được điều khiển tự động. Chúng ta có thể điều chỉnh áp suất và tần số xung, tùy vào tình trạng tắt nghẽn của khuôn khác nhau, để đánh bay cáu cặn, rỉ sét và chất gây trở ngại khác ở thành trong ống dẫn khuôn. Hướng của hỗn hợp được giải phóng có thể thay đổi, nên khi máy hoạt động, thành trong của ống dẫn khuôn sẽ được rửa nhiều lần và đánh bật theo cả hai hướng, do đó cáu cặn và rỉ sét ở thành trong được loại bỏ. Cuối cùng, cáu cặn và rỉ sét được tách rời sẽ được thu gom và thải ra ngoài.

Những tiến bộ và ưu điểm|

THÔNG SỐ KỸ THUẬT |

|||||

| MODEL | CMG-11 | CMG-15 | CMG-22 | CMG-30 | CMG-55 |

| Cleaning media | Water or cleaning agentia | ||||

| Operational method | 7" PLC touch screen | ||||

| Water tank capacity | 40L | 100L/50L+50L | 100L/50L+50L | 120L/60L+60L | 150L |

| Water tank quantity | One | One or Two | One or Two | One or Two | One |

| Input & output specification | 3/8"*4 | 3/8"*8 | 3/8"*8+1"*2 | 1/2"*8+1.5"*2 | 1/2"*8+2"*2 |

| Machine power | 1.1 KW | 1.5 KW | 2.2 KW | 3.0 KW | 5.5 KW |

| Power supply | AC220V 1P+N+E / AC380V 3P+N+E | ||||

| Machine dimension | 1000*500* 800mm | 1400*500* 1200mm | 1400*500* 1200mm | 1600*600* 1200mm | Customized |

| Machine weight | 180 Kg | 300 Kg | 320 Kg | 350 Kg | |

| Water tank automatic heating | NO | Optional | Optional | Optional | Optional |

| 10" touch screen | NO | Optional | Optional | Optional | Optional |

| 1000 sets cleaning record | Optional | Optional | Optional | Optional | Optional |

| SUS304 structure | YES | YES | YES | YES | YES |

| SUS316 structure | Optional | Optional | Optional | Optional | Optional |

|

|

|

||||||||||

| Trước khi làm sạch | Sau khi làm sạch | Cáu cặn, rỉ sét và chất bẩn sau khi làm sạch | ||||||||||

|

|

|

||||||||||

| Trước khi làm sạch | Sau khi làm sạch | Cáu cặn, rỉ sét và chất bẩn sau khi làm sạch | ||||||||||

|

|

|